- HOME

- RESISTENZE CORAZZATE

- RESISTENZE CORAZZATE TUBOLARI

- RESISTENZE CON CAVI

- RESISTENZE CON TERMOSTATO E TELERUTTORE

- RESISTENZE CORAZZATE PER SCIOGLIMENTO FONDAMI

- RESISTENZE CORAZZATE LOR-FLEX

- RESISTENZE CORAZZATE ALETTATE

- BATTERIE ELETTRICHE

- RESISTENZE CORAZZATE SU FLANGIA

- RESISTENZE PER GRUPPO BOILER

- RISCALDATORI ANTICONDENSA

- RISCALDATORI MONOTUBO PER IMPIANTI LAVAGGIO E ALIMENTI

- RISCALDATORI MONOTUBO PER BAGNI SPECIALI

- RESISTENZE IN TEFLON

- QUADRI ELETTRICI

- TERMOSTATI

- SCATOLE DI PROTEZIONE IP65

- RISCALDATORI PER GALVANICA

- RESISTENZE ELETTRICHE ATEX

- RESISTENZE PER SCALDAFUSTI E CISTERNETTE

- RISCALDATORI ANTICONDENSA

- RESISTENZE A CARTUCCIA E MICROTUBOLARI

- RESISTENZE UGELLO-FASCIA-PIATTE

- RISCALDAMENTO ELETTRICO A PAVIMENTO

- NO FROST PHOTOVOLTAIC SYSTEM

- CAVI SCALDANTI AD USO DOMESTICO

- CAVI INDUSTRIALI

- CONTROLLO DELLA TEMPERATURA

- CONTACT INFORMATION

- DOWNLOAD

- OUR STORY

- HOME - ENGLISH

- ARMORED HEATERS

- TUBULAR HEATERS

- HEATERS WITH CABLES

- ARMORED HEATERS WITH THERMOSTAT AND REMOTE CONTROL SWITCH

- ARMORED HEATERS FOR DISSOLUTION OF HEAVY OILS

- LOR-FLEX FLEXIBLE HEATERS

- FINNED HEATERS

- DUCT HEATERS

- FLANGED HEATERS

- HEATERS FOR BOILERS

- ANTI-CONDENSATION HEATERS

- SINGLE-TUBE HEATERS FOR WASHING AND FOOD SYSTEMS

- SINGLE-TUBE HEATERS FOR SPECIAL BATHS

- PTFE IMMERSION HEATERS

- ELECTRICAL PANELS

- THERMOSTATS

- IP65 PROTECTION CASINGS

- GALVANIC HEATERS

- HEATERS ATEX IECEX CERTIFIED

- DRUM HEATERS AND HEATING JACKETS

- ANTI-CONDENSATION HEATERS

- CARTRIDGE HEATERS AND MICROTUBULAR HEATERS

- NOZZLE HEATERS - BAND - PLATE

- UNDERFLOOR HEATING SYSTEM

- HEATING CABLES FOR INDUSTRIAL USE

- OUR STORY

- ARMORED HEATERS

- HOME - ESPAÑOL

- RESISTENCIAS ELÉCTRICAS ACORAZADAS

- RESISTENCIAS ELÉCTRICAS ACORAZADAS TUBULARES

- RESISTENCIAS ELÉCTRICAS CON CABLES

- RESISTENCIAS ELÉCTRICAS ACORAZADAS CON TERMÓSTATO Y TELERRUPTOR

- RESISTENCIAS ELÉCTRICAS ACORAZADAS PARA LA DISOLUCIÓN DE RESIDUOS

- RESISTENCIAS ACORAZADAS FLEXIBLES LOR-FLEX

- RESISTENCIAS ACORAZADAS ALETADAS

- BATERÍAS ELÉCTRICAS PARA EL CALENTAMIENTO DEL AIRE

- RESISTENCIAS ELÉCTRICAS ACORAZADAS BRIDADAS

- RESISTENCIAS ELÉCTRICAS PARA CALENTADORES ELÉCTRICOS

- CALENTADORES ANTICONDENSACIÓN

- RESISTENCIAS MONOTUBO PARA INSTALACIONES DE LAVADO Y ALIMENTOS

- CALENTADORES MONOTUBO PARA BAÑOS ESPECIALES

- RESISTENCIAS ELÉCTRICAS DE TEFLÓN

- ARMARIOS DE CONTROL

- TERMOSTATOS

- CAJA DE PROTECCIÓN IP65

- CALENTADORES PARA GALVÁNICA

- RESISTENCIAS ELÉCTRICAS ATEX

- RESISTENCIAS PARA TAMBORES Y MANTAS CALEFACTORAS

- CALENTADORES ANTI-CONDENSACIÓN

- RESISTENCIAS DE CARTUCHO Y MICROTUBULARES

- RESISTENCIAS DE BOQUILLA – TIPO BANDA – PLANAS

- SUELO RADIANTE ELÉCTRICO

- CABLES CALEFACTORES DE USO DOMÉSTICO

- CABLES CALEFACTORES ANTICONGELANTE PARA SUPERFICIES TRANSITABLES EXTERIORES

- CABLES CALEFACTORES ANTICONGELANTE PARA TUBERÍAS

- CABLES CALEFACTORES PARA INSTALACIONES SANITARIAS

- CABLES CALEFACTORES ANTICONGELANTE PARA TEJADOS, ALEROS Y BAJANTES

- CALEFACCIÓN POR SUELO RADIANTE ELÉCTRICO

- PROTECCIÓN ACTIVA DE PUENTES TÉRMICOS

- ARMARIOS DE CONTROL

- CABLES CALEFACTORES DE USO INDUSTRIAL

- RESISTENCIAS ELÉCTRICAS ACORAZADAS

SINGLE-TUBE HEATERS FOR SPECIAL BATHS

SINGLE-TUBE HEATERS

STRAIGHT AND SMALL

Single-tube heaters are the most suitable type of electrical heating for a wide range of process fluids.

Excellent corrosion resistance is ensured by the use of various types of materials. The various mounting possibilities respond to the most different heating needs. The use of materials with a high quality standard is a guarantee of a long life and a high reliability of our products, which allow you to operate plants at a low rate of faults.

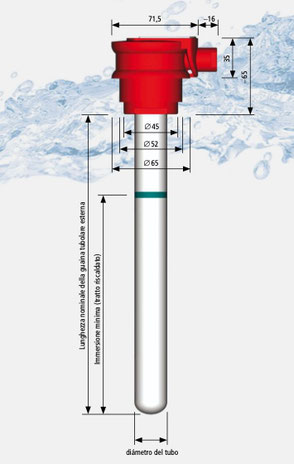

This kind of tubular heater has a modular structure and it consists of an outer tubular sheath (built from different types of materials), a "long-life" heating cartridge (inner thermal field), a terminal casing, a power cord (optional).

OUTER TUBULAR SHEATH

We can offer you the most suitable materials for each application. The heating section has a permanent ring marking (minimum immersion length) and it is equal to about two-thirds of the normal length of the tube. The part of the pipe that stays above the marking is not heated. The heated part must always be immersed in the liquid even at a large variation of the liquid level.

"LONG-LIFE" HEATING CARTRIDGE

"Long-life" heating cartridges have grooved bodies made of a ceramic material with a high degree of electrical insulation and a good mechanical strength. Resistive coils are built with specific filaments withstanding high temperatures; the design parameters ensure an optimal flow of thermical energy to the fluid to be heated.

Heating cartridges are available in a wide range of supply voltages, up to a maximum of 500V (250V in the small version) with a single-phase or three-phase connection.

BC COVERS PROTECTION

The standard terminal block is made of polypropylene. Good mechanical, thermical and chemical resistance ensures their use with the majority of process liquids. At very high temperatures (more than 80°C) or with strong anti-oxidant substances (e.g. Electrolytes of chromium or HNO3) PVDF (BC/L) protection is recommended. The protection rating is IP65 (EN_60529).

Supply cable connection is also possible with the mounted protection, by removing the cover using the SB mouting key.

POWER CORD

Generally PVC power cord is 1,6m long. Cords of different lengths are available upon request.

ELECTRICAL SAFETY

According to the normative EN_60519/1-2, tubular heaters belong to class I protection. All metal parts are connected to the protection lead. In order to ensure the grounding protection even to non-electro-conductive sheaths, a protective coil is mounted on the heating cartridge. If the supply circuit provides differential protection, maximum electrical safety is guaranteed.

All single-tube heaters are manufactured under the VDE brand name.

SINGLE-TUBE HEATERS WITH FIRE CONTROL SYSTEM

Single-tube heaters with ABS (Anti-Burn System) minimize possible thermical damages to the systems and tanks in case of complete or partial loss of the liquid to be heated. The normative EN_60519/1-2 specifies that the system electrically heated must be equipped by the user with a technology that allows safe use (protection against overheating and against dry operation).

However, even the best saftey technology cannot protect systems from errors made by operators or from incorrect maintenance.

The following "critical" situations in liquid solutions up to 100°C can be avoided by using an immersion safety heater with an anti-burn system:

- Operation of the heater also at a low level of liquid (due, for example, to the evaporation of the fluid);

- Operation of the heater also in absence of liquid (due, for example, to a sudden and unexpected loss of fluid);

- Operation of the heater when the heat transfer from the tube of the immersion heater to the fluid is reduced (due, for example, to high fouling on the immersion tube).

Safety immersion heaters in the straight range with an anti-burn system can take both vertical and horizontal positions in tanks and other systems. This flexibility simplifies safety immersion heaters processes of planning and installing, in order to cope with a wide range of requirements for such applications.

SINGLE-PHASE OR TWO-PHASE CONNECTION

The integrated anti-burn system blocks too high temperatures and turns off the heater. The heater remains off until the safety circuit is manually reset. This can be done only if the other safety devices are used correctly, and both the tank and the heater are in a good condition. Heater cartridges are available for all stated voltages up to 400V and with a given power up to 6.0 kW.

THREE-PHASE CONNECTION

When the immersion tube reaches a temperature that is too high, the integrated anti-burn system disables the resistor using an electronic device called DSW 3/2 and a power relay. The heater is then switched off until the safety circuits in the immersion resistor and the electronics are manually restored. The anti-burn system can be installed in all three-phase resistors with rated voltages up to 400V and a current consumption from 1.8 to 16A.

ANGULAR TUBULAR HEATERS

Angular tubular heaters are a form of direct electric heating that is the most suitable for all containers with a low or very variable level of fluid.

The heated horizontal outer tubular sheath allows heating from the bottom of the vessel and ensures an optimal flow of thermal energy to the fluid, as well as a good distribution of heat. Nominal power is determined decisevely by the length of the horizontal outer tubular sheath, since you can take advantage of the entire length for heating, a relatively high power is also possible. The unheated vertical outer sheath can be individually adapted to the depth of the vessel. These costum sizes virtually allow any adaptation to vessel geometry.

The structure reduces the footprint, thus making the design more effective and cheaper. Angular tubular heaters include the horizontal heated outer tubular sheath with a "long-life" heating cartridge, a vertical unheated outer tubular sheath, a terminal casing and a power cord.

OUTER TUBULAR SHEATH

The horizontal outer tubular sheath is welded to the vertical one. The excellent resistance to corrosion is ensured by the use of different metallic materials of the sheath. The use of different sheath materials with a high quality standard is a guarantee for a long life and a good reliability of our products, which allows you to operate plants at a low rate of faults. To comply with the minimum distance from the bottom of the vessel or for fixing, the angular support feet are welded on the horizontal outer tubular sheath.

"LONG-LIFE" HEATING CARTRIDGE

The "long-life" heating cartridges have grooved bodies made of a ceramic material with a high degree of electrical insulation and a good mechanical strength. Resistive coils are built with special filaments that withstand high temperatures, and the design parameters ensure an optimal flow of thermal energy to the fluid to be heated. Heating cartridges for angular tubular heaters are available in a wide range of supply voltages up to 500V (250V in the small version), with a single-phase or three-phase connection.

TERMINAL CASING

The standard BC terminal casing for angular tubular heaters is made of polypropilene. Good mechanical, thermal and chemical resistance ensures they can be used with the majority of process liquids.

At very high temperatures (>80°C) or with strong oxidising substances (e.g. Electrolytes of chromium or HNO3), the BC/L PVDF protection is recommended. The protection rating is IP65 (EN_60529).

Cable connection is also possible with the mounted protection, by removing the cover using the SB mounting key.

POWER CORD

Generally PVC power cord is 1,6m long. Cords of different lengths are available on demand.

ELECTRICAL SAFETY

We draw attention to the fact that, according to EN_60519/1-2 regulations, users of electric heating systems must ensure their electrical safety (protection against overtemperature and drying).

To achieve this, the optimal solution is to use our level or floating rods with built-in thermal resistors and the related electronic components.

We dispose of a complete range of single-tube heaters, stainless steel plug, 45/63.5 diameter, IP65 protection, Aisi 316 sheath, Sheath made of special heavy vitrified potter (54 or 28 diameter) available in stock.

We produce any other type of single-tube upon specific technique.

HEATERS FOR GALVANOTECHNICS

SINGLE-TUBE HEATERS

Single-tube heaters for galvanotechnics