- HOME

- RESISTENZE CORAZZATE

- RESISTENZE CORAZZATE TUBOLARI

- RESISTENZE CON CAVI

- RESISTENZE CON TERMOSTATO E TELERUTTORE

- RESISTENZE CORAZZATE PER SCIOGLIMENTO FONDAMI

- RESISTENZE CORAZZATE LOR-FLEX

- RESISTENZE CORAZZATE ALETTATE

- BATTERIE ELETTRICHE

- RESISTENZE CORAZZATE SU FLANGIA

- RESISTENZE PER GRUPPO BOILER

- RISCALDATORI ANTICONDENSA

- RISCALDATORI MONOTUBO PER IMPIANTI LAVAGGIO E ALIMENTI

- RISCALDATORI MONOTUBO PER BAGNI SPECIALI

- RESISTENZE IN TEFLON

- QUADRI ELETTRICI

- TERMOSTATI

- SCATOLE DI PROTEZIONE IP65

- RISCALDATORI PER GALVANICA

- RESISTENZE ELETTRICHE ATEX

- RESISTENZE PER SCALDAFUSTI E CISTERNETTE

- RISCALDATORI ANTICONDENSA

- RESISTENZE A CARTUCCIA E MICROTUBOLARI

- RESISTENZE UGELLO-FASCIA-PIATTE

- RISCALDAMENTO ELETTRICO A PAVIMENTO

- CAVI SCALDANTI AD USO DOMESTICO

- CAVI INDUSTRIALI

- CONTROLLO DELLA TEMPERATURA

- CONTACT INFORMATION

- OUR STORY

- DEXTER VINTAGE

- HOME - ENGLISH

- ARMORED HEATERS

- TUBULAR HEATERS

- HEATERS WITH CABLES

- ARMORED HEATERS WITH THERMOSTAT AND REMOTE CONTROL SWITCH

- ARMORED HEATERS FOR DISSOLUTION OF HEAVY OILS

- LOR-FLEX FLEXIBLE HEATERS

- FINNED HEATERS

- DUCT HEATERS

- FLANGED HEATERS

- HEATERS FOR BOILERS

- ANTI-CONDENSATION HEATERS

- SINGLE-TUBE HEATERS FOR WASHING AND FOOD SYSTEMS

- SINGLE-TUBE HEATERS FOR SPECIAL BATHS

- PTFE IMMERSION HEATERS

- ELECTRICAL PANELS

- THERMOSTATS

- IP65 PROTECTION CASINGS

- GALVANIC HEATERS

- HEATERS ATEX IECEX CERTIFIED

- DRUM HEATERS AND HEATING JACKETS

- ANTI-CONDENSATION HEATERS

- CARTRIDGE HEATERS AND MICROTUBULAR HEATERS

- NOZZLE HEATERS - BAND - PLATE

- UNDERFLOOR HEATING SYSTEM

- HEATING CABLES FOR INDUSTRIAL USE

- OUR STORY

- ARMORED HEATERS

SINGLE-TUBE HEATERS FOR WASHING AND FOOD systems

CARTRIDGE HEATERS

Cartridge heaters are particularly suitable for direct heating of washing fluids and of alkalin solutions. In order to allow a maximum freedom of chioce in the design of the plant, we adapt our products to specific needs:

- Cartiridge heating bodies without outer tubular sheaths, in varied diameters, installation lengths and specific loads, costumized according to different requirements.

- Cartridge heating bodies with outer tubular sheaths of varied materials and with multiple fixing possibilities such as flanges or threaded nipples.

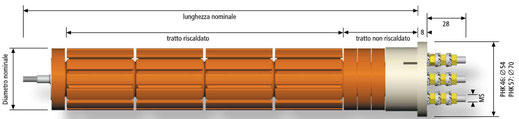

SPECIFICATIONS OF CARTRIDGE HEATERS

Cartridge heating bodies have grooved bodies made of a ceramic material with a high degree of electrical insulation, a good mechanical strength and an excellent resistance to temperature changes. Resistive coils are built with high temperature resistant filaments; design parameters ensure an excellent thermal conductivity and a long service life. Under the connecting head, there is a 50mm unheated area. This unheated section can be extended on request.

Heating cartridges are available in a wide range of supply voltages, up to a maximum of 500V, with a single-phase and a three-phase connection. The modular structure allows us to make costumized solutions at any time by variations in rated length, rated voltage and rated power.

MATERIAL SPECIFICATIONS OF THE OUTER TUBULAR SHEATHS

Depending on the conditions of use and requirements, we offer you different materials with different types of fastening. In our llst, corrosion heaters of single materials are represented in a different way. The surface load of the outer tubular sheath depends on the type of use. The ability to costumize projects is a guarantee of long life and a low rate of faults functioning.

SAFE AND QUALITY WARNING

POSSIBILITIES OF FIXING TERMINAL CASINGS OF OUTER TUBULAR SHEATHS

We have provided for a variety of fixing options for your applications. Depending on the type of application, the outer tubular sheaths can be supplied without a fiixng flange, with a welded or screwed flange or threaded nipple.

If there are more outer tubular sheaths placed close to each other, we recommend fitting a central terminal casing. If there are only single outer tubular sheaths or there is a large distance between them, a special protection must be selected for each sheath.

As a single protection, you can choose between BC 62 polypropylene (PP) or BC 62/L polyvinylidene fluoride (PVDF) terminal casings.

With the SB mounting key, the protection is quick and easy to mount. Alternatively, especially for high temperatures, you can also use the B galvanized steel terminal casings.

ELECTRICAL SAFETY

According to EN_60519/1-2, cartridge heating bodies are classified as class I protection devices.

All contact metal parts (outer tubular sheaths) are connected to the protection lead.